Dry Sand Suction Machine For River Banks

Tuesday September-09 2025 11:15:29

Dry Sand Suction Machine For River Banks solves the problem that dry sand materials are prone to "bridges" and blockages during the transportation process, and require flexible movement and transportation to different locations. During operation, the motor drives the spiral shaft to rotate, and the spiral blades push dry sand to move along the inner wall of the fixed hose. The spiral lifting angle of the spiral blades is used to transport dry sand from the feed port to the discharge port. The hose can flexibly adjust the conveying direction to adapt to complex working conditions. Affected by the spiral diameter, rotation speed, and dry sand bulk density, the common single conveying volume is usually 1-20m³/h.

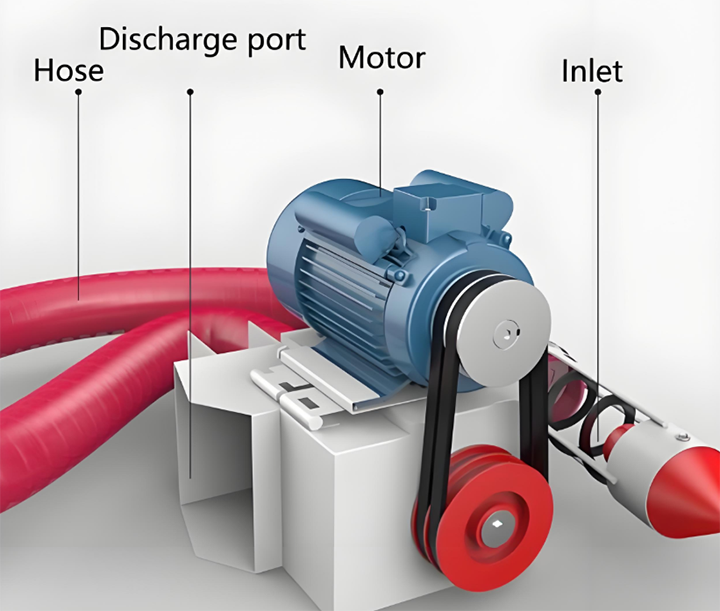

Dry Sand Suction Machine For River Banks Structure

Dry Sand Suction Machine For River Banks mainly consists of motors, feed ports, screw conveyor components, hoses and discharge ports. The motor provides power and drives the spiral conveying components to operate through the transmission device; the material enters from the feed port, is pushed through the spiral conveying components, is conveyed in the hose, and is finally discharged from the outlet. The hose acts as a conveying channel to adapt to the dry sand transmission needs under different working conditions.

Advantages of Dry Sand Suction Machine For River Banks

Dry Sand Suction Machine For River Banks' own structure has the advantages of flexibility, no blockage, good sealing, easy installation, and space saving.

No-blocking design: This is the most important advantage. The forced push of the spiral ensures that even completely dry and extremely poor fluid sand can be transported out stably and continuously, ensuring the working efficiency and continuity of the entire suction machine.

Great flexibility: The hose can be bent to a certain radius, and the outlet direction of the conveyor can be flexibly adjusted. The operator can easily transport sand to truck containers or stacking points in different directions and locations without moving the entire machine.

Good sealing, environmentally friendly and dust-free: the entire conveying process is carried out in a sealed hose, effectively controlling the flying of sand and dust, meeting production requirements, and protecting the health of operators. At the same time, it avoids omissions and waste of materials.

Easy to install and relatively easy to maintain: Compared with complex rigid pipes and hinge systems, Dry Sand Suction Machine For River Banks has a simple structure and is very easy to install and disassemble. If the hose or the coil spring inside wears, it will also be faster and less expensive to replace than the metal conveyor tank for repair.

Suitable for equipment with limited space: Dry sand suction machines need to move on the river beach, and the equipment requires compact structure. Dry Sand Suction Machine For River Banks can be designed to be relatively lightweight and can be bent and folded when not in use, saving space.

Dry Sand Suction Machine For River Banks Price

The price of Dry Sand Suction Machine For River Banks is related to the pipe diameter and length, conveying capacity, hose material, drive and control system, etc. Common hoses have diameters such as Φ50, Φ63, Φ75, Φ100, Φ150mm, etc. The larger the diameter, the larger the conveying volume, and the higher the price. The hose is made of ordinary PVC/PU tube, with the lowest price, wear-resistant polyurethane (PU) tube, medium price, and the highest price of stainless steel tube. Among them, PU tubes are often used for dry sand and other materials with strong abrasive properties. When selecting, you can select the information about the device according to the specific situation.

Dry Sand Suction Machine For River Banks are essential in the river bank, with high friction and poor fluidity between dry sand particles. This equipment can solve the problem of dry sand transport. Dry Sand Suction Machine For River Banks produced by our factory are used in building materials, food and other industries. The company can customize non-standardly according to the conveying volume, specific working conditions, materials and other requirements, and also supports material testing machines to meet customer needs.